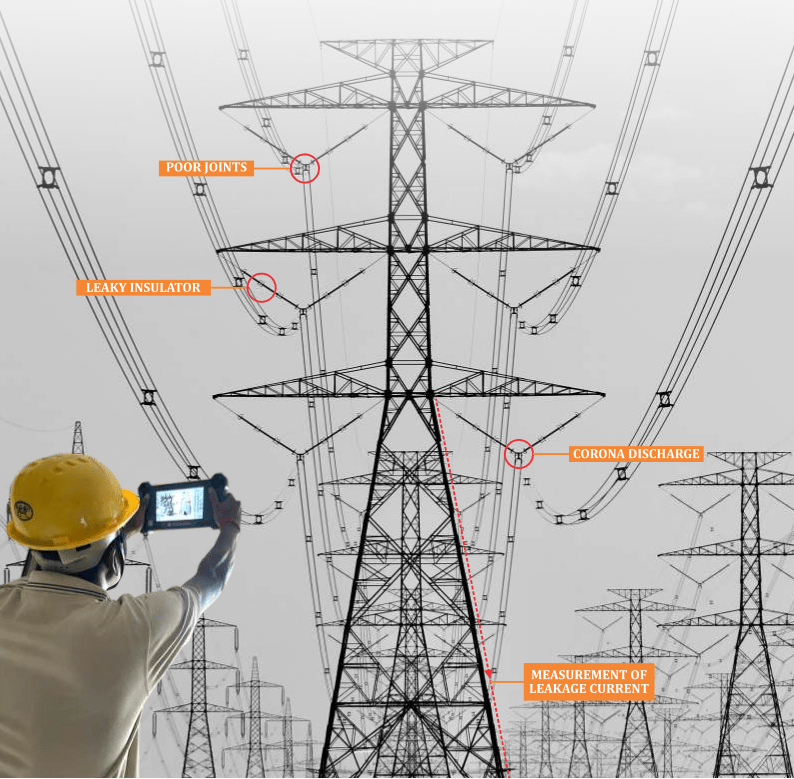

At Taurus Powertronics, we’re dedicated to ensuring the integrity and safety of your transmission lines with our cutting-edge technology. Our Leaky Insulator Detector with Video Partial Discharge (LIDVPD) system revolutionizes predictive maintenance, offering you peace of mind and reliability.

Detecting Leaky Insulators with Precision

Our LIDVPD system combines AC/DC current sensing and ultrasonic technology for accurate predictive maintenance. With a flexible clamp sensor and ultrasound imager, we can identify and locate potential issues before they escalate, saving you time and resources.

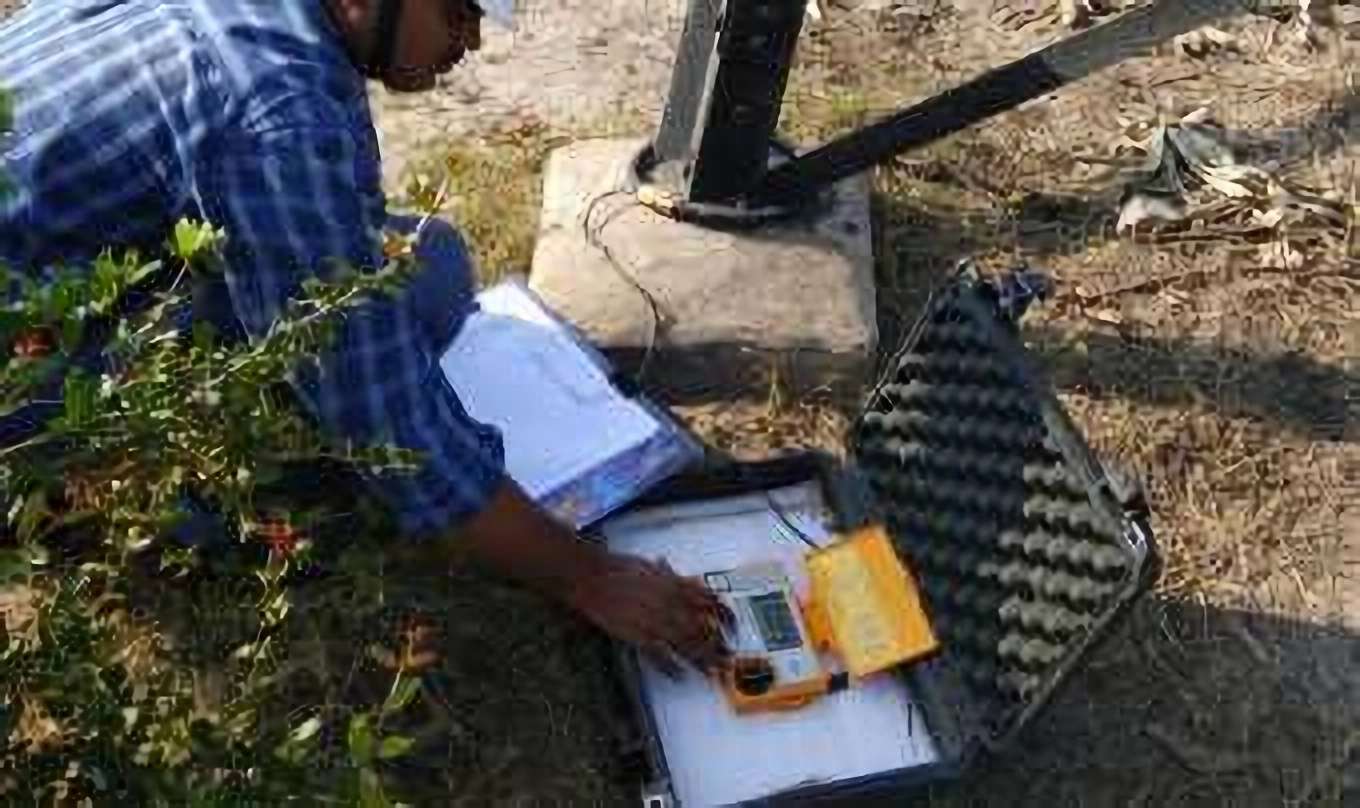

How It Works

- Leakage Current Measurement: Our system measures leakage current in all four legs of your transmission towers, summing it up to determine if it exceeds safe limits.

- Ultrasound Imaging: The ultrasound imager scans insulator strings, pinpointing the exact location of any leaks or partial discharge arcing, providing graphical evidence for future reference.

Advantages of Choosing Taurus Powertronics

- Improved Safety: Our handheld device allows for safe testing of transmission towers and critical equipment from a distance, reducing risks and improving safety practices.

- Early Detection: By detecting ultrasound produced by arcing and corona discharge, we enable early monitoring and intervention, preventing costly breakdowns.

- Accuracy and Reliability: Tested alongside competitive technologies, our LIDVPD system offers superior accuracy and reliability in detecting insulation issues.

- Enhanced Power Transmission: By routinely monitoring transmission lines and transformers, our system helps optimize power transmission, minimizing grid failures.

Why Choose Us

- Advanced Technology: Our ultrasound imager can detect ultrasound from up to 100 meters, allowing for efficient detection of leaks even at great heights.

- Cost-Effective: With our system, you can locate leaks without the need for climbing ladders or using lifts, saving time and resources.

- Comprehensive Fault Detection: From identifying partial discharge to pinpointing faults at lightning arresters and contaminated insulators, our system offers comprehensive fault detection.

- Wide Range of Applications: Our system is not limited to transmission lines; it can also be used for testing equipment in generating stations and other power sector applications.

Specifications

Functional Requirement : Leaky Insulator Detector with Video Partial Discharge measures Tower Leakage Current & Visually detect of Ultrasound Partial Discharge to identify the leaky insulators.

Memory : Instrument should have internal memory storage up to 8GB

72 sealed microphones (spiral array) for use in industrial areas

Real-time acoustic results at 100 fps for real time results

Wide frequency range : 10 Hz to 100 kHz for the detection of audible sound and ultrasound

Integrated data acquisition and analysis software

Handheld device with IP54 protection (splash proof)

Integrated LED lights

8 configurable buttons for fast control

Low weight and small size

Type of CT sensor : Flexible Split-Core Type

Inside Diameter : φ200 mm or φ400mm (User Selectable)

Measuring Function : AC/DC Leakage/Line Current

Measuring Method : Dual Integration Mode

Measuring Range : AC/DC 3A/30A/300A/3000A (AC50/60 Hz & DC)

Accuracy : ±3% of reading

Display : LCD max. 3200 reading with Annunciators

Low Battery Indication : B” mark on LCD

Data Hold Function : “DH” Switch

Zero Adjustment : DC current range, by “0 SET” switch

Power Supply : 1.5V (AA size, UM-3) ×6

Calibration Certificate : Calibration Certificate to be provided from any NABL accredited laborator