SF6 SOLUTIONS

SF6 gas analysis

SF6 Gas Recovery & Transfer units with inline filtration

Sf6 leak detection

Application field:Sf6 gases are widely used gases for GIS substations and the AIS substation circuit breakers. It is one of the best insulation mediums for circuit breakers. But by using the Sf6 we have to maintain some of the quality and the safety protocols for the smooth operation of the Circuit breakers.

Features

- Modular sensor choice

- 7” full-color touchscreen

- Vacuum line purge

- Walk away timer

- Auto abort function

- Auto clean function

- Fully automatic testing and data logging

- Gas cylinder testing mode

- Multi language

- Vehicle charger

- Inbuilt CIGRE & IEC Tests

- We have 4 gases and 6 gases model

- 100 % Oil Less Compression

- SF6 Gas Recovery Up to Desired Vacuum Level (< 50 mbar)

- Inline Separate Standalone Filter

- Recovery of SF6 Gas direct to Auxiliary Empty Cylinder up to 50Bar

- Microprocessor controlled circuit with Advanced Digital Signal Processing

- Detects SF6 & all halogenated refrigerants

- Variable frequency audible alarm

- Constant power indication

- Cordless and portable; operates on two C-cell batteries

- 14"(35.5cm) flexible stainless-steel probe with line

- Carrying case included, optional holster

- Optional reference leak source

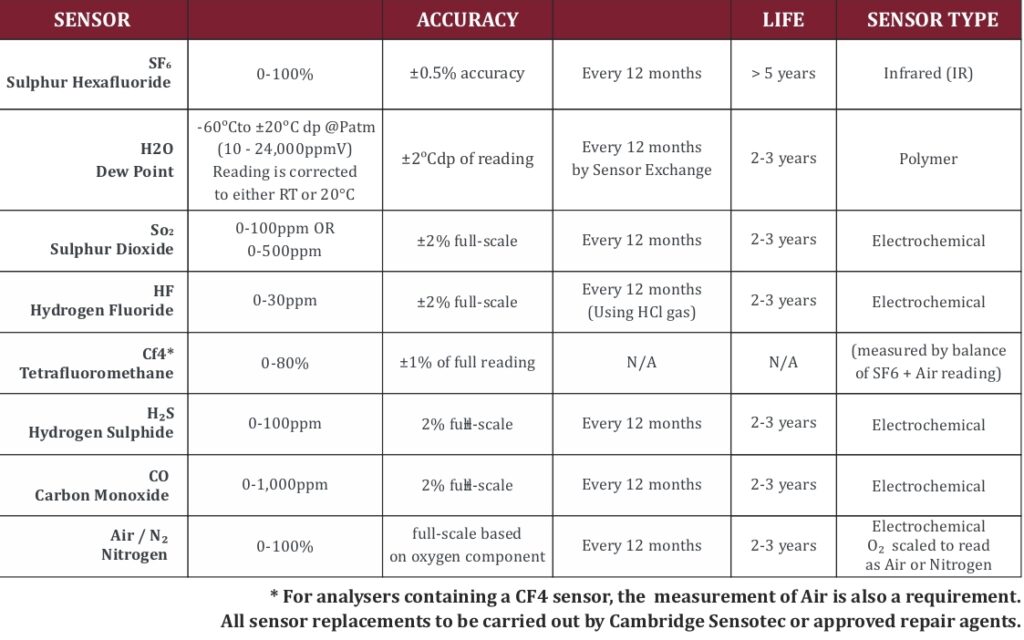

Technical Specifications:

- SF6 6100 PUMP BACK SPECIFICATION

- Ambient Operating Conditions: -10°C to +55°C, 10-90% RH, 800-1100mbar

- Warm-up Time: 3-4 minutes at 20C

- Voltage (Charging): 90-260 VAC, 50/60Hz

- Power Supply : Two (2) Standard AAA Alkaline Batteries (for laser) and one 9V alkaline battery (for Receiver unit)

- Battery Life: Up to 8 hours. 4–6-hour charge

- Sample Connections Special tongue and groove self-sealing couplings (compatible with famous brands)

- Data Outputs Excel compatible data via USB memory stick

- Data Storage 4GB internal data storage allowing for approximately 1 year of continuous monitoring

- Compressor Up to 35 Bar with up to 25 cycles per battery charge

- Measurement Time: 8 minutes

- Pressure Range: 0.5-35 Bar; displayed on screen

- Gas Flow Rate: 0.5l.min-¹

- Max Inlet Pressure: 35 Bar gauge

- Display: 7” (180mm) full-colour LCD touch screen interface with soft menu keys

- Printer Integrated thermal printer allows output of results on demand

- Analyser Dimensions: 270mm(H) x 560mm(W) x 450mm(D)

- Weight: 21kg (total instrument and case)

SF6 GAS RECOVERY & TRANSFER UNITS WITH INLINE FILTRATION SPECIFICATION (SFX)

- The Unit has mainly two compartments, one recovery unit and the second is a storage tank.

- The complete unit is MS Fabricated with a powder-coated finish for long-lasting rust proof performance.

- 440 V, 50 Hz 3 Phase supply with permanent 5 meters be the detachable power cord.

- Separate Electrical Panel with standard power and control gears. Front-mounted process selection switches and indication.

- A 100% Oil-Less Direct Drive 12m3/r Compressor having compression capacity in both stages i.e., in liquid and vapour up to 50 Bar. (Optional compressor of 5.8 m3/hr & 15 m3/hr available).

- Direct Drive Vacuum Compressor of a capacity of 5.8m3/hr.

- Inbuilt 40m3/Direct Drive Vacuum pump – allows vacuum up to 0 mbar Abs (-1 bar). Vacuum pump motor 2 HP, 1500 rpm, TEFC motor. (Optional Vacuum pump of 60 m3/hr. & 100 m3/hr. available)

- Vacuum pump is equipped with an anti- suck back valve to prevent the reverse flow of oil towards the compartment in case of power failure.

- Separate Digital Absolute indicator with a range of 0 to 700 mbar for Vacuum level measurement and hold function.

- Specially designed SF6 Refrigerated Condenser to aid in liquefaction.

- Particle Filter – 1 Micron Fiber Media with a replaceable cartridge.

- Reporting Software : Available with Trend Analysis Chart

- Drier Filter – Sealed Molecular sieve filter to remove moisture and arcing by-products.

- Permeation resistant hoses: 5 meters long complete with Quick Release Coupling DN20 at one end and other ends suitable to DN20 type SF6 Connectors.

- Digital Pressure Indicator for Recovery, Storage and Vacuum process.

- Separate Isolation Valve and Easy to read 4” Pressure indicator on Storage Tank and DN20 pipelines; High-pressure auto reset safety pressure release valve.

- Mounted on 8” rubber wheel with steerable trolley - provides efficient mobility in switchyard area.

- Recovery Unit Chases - Totally Enclosed Fan Cooled system makes it possible to work at an ambient 45 ºC.

- All Internal pipeline of Copper and Brass Fittings, with Non-Return Valve to prevent back flow.

REFRIGERANT LEAK DETECTORS SPECIFICATION (TIF XP-1/RX-1)

- Power Source 3V DC; 2 “C” cell alkaline batteries

- Ultimate Sensitivity || TIFXL-1A - Less than 0.4 oz./yr. || (11g/yr.) TIFRX-1A - Less than 0.25 oz./yr. (7g/yr.) || TIFXP-1A - Less than 0.1 oz./yr. (3 g/yr.)

- Sensing Tip Life: Approx. 20 hours

- Operating Range: 30° to 125° F (0° to 52° C)

- Battery Life : TIFRX-1A and TIFXP-1A – Approx. 30 hrs. || TIFXL-1A – Approx. 40 hrs.

- Duty Cycle: Continuous

- Response Time: Instantaneous

- Reset Time: One second

- Warm-up Time: Approx. 2 seconds

- Unit Weight: 1.2 lbs. (560 grams)

- Unit Dimensions: 9" x 2.25" x 2.25" (22.9 cm x 5.7 cm x 5.7 cm)

- Fixed Probe Length: 14" (35.5 cm)