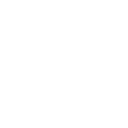

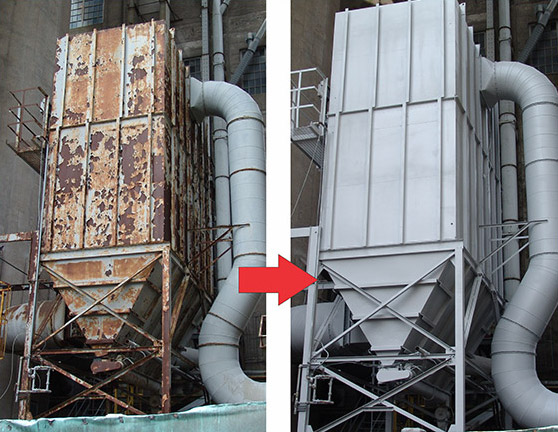

BEFORE & AFTER

UV resistant, liquid elastomeric coating system which dries to a highly durable, seamless, weather resistant, protective ‘skin’.

ENESEAL CR is a single component, water based, liquid coating which dries to a highly durable, corrosion resistant, elastomeric ‘skin’ that provides extraordinary environmental protection to metal and concrete / masonry surfaces. It can also be applied as a top coat over most zinc primers.

ENESEAL CR is a ‘surface tolerant’ coating system that does not require abrasive blasting. It exhibits excellent adhesion to all types of ferrous metal as well as galvanized surfaces. Mechanical wire brushing, grinding or high pressure water blasting is typically acceptable to achieve good adhesion.

ENESEAL CR incorporates a unique blend of corrosion inhibitors, UV resistant resins and pigments, erosion resistant inorganic fillers and elastomeric acrylic polymers in order to provide outstanding performance in all types of demanding industrial and marine environments. Easily applied by brush, roller or spray, ENESEAL CR cleans up quickly and easily with just soap and water.

Features

- Unit Size: 20 kg / 8 kg

- Color: White, Light Gray, Green, Brown, Safety Yellow

- Finish: Satin

- Volume Solids: 58%

- Vehicle Type: Water based elastomeric acrylic polymer.

- Recommended Film Thickness: 12-14 mils WFT per coat. 7-8 mils DFT per coat.

- Coverage Rate: Approx. 500 sq. ft. per 20 kg unit per coat @ 12 mils WFT based on a smooth substrate. Rough substrates will

- Shelf Life: 3 years in an unopened container. Do not allow to freeze.

- Overcoating: 4 hours minimum (16+ hours optimum)

- Elongation: 300% - (ASTM D-2370)

- Tape Adhesion: 5A (ASTM D-3359 Method A) Wire-brushed steel substrate.

- Direct Tensile Adhesion: 850 psi (ASTM D-4541) Wire-brushed steel. 900 psi (ASTM D-4541) Galvanized steel.

- Water Vapor Transmission: 1.14 g / h*m2 - (ASTM E-96)

- Spraying: Airless spray. Minimum pressure: 2,500 psi Tip orifice: 0.013 to 0.043

USE ON :

- Steel work

- Decks

- Pipes

- Ducts

- Concrete

- Wood

- Metal roofs

- Galvanizing

- Bridges

- Tanks