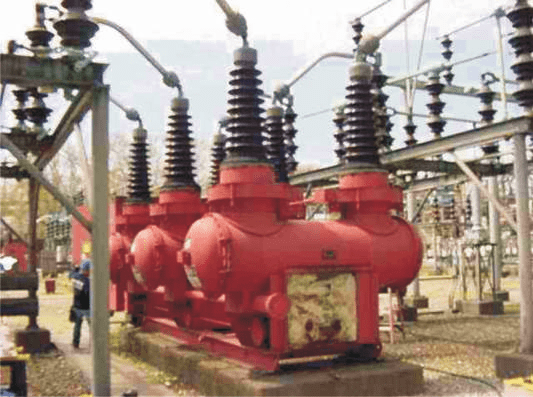

DurAlloy Stops Critical SF-6 Gas Leaks

A major Northeastern U.S. utility company was experiencing SF-6 gas leaks on its substation breakers. Cracks in the old solder joints were causing this gas to leak from the insulator bushing caps. SF-6 gas has excellent cooling and insulation capabilities. However, SF-6 gas is an expensive and ozone-depleting gas, so leaks are unacceptable. In the past, the utility company’s engineers were repairing these leaks by soldering, but only with limited success.

Recently, the local ENECON distributor was asked to provide a proposal to repair the leaks with DurAlloy. First, the old solder and paint were stripped away from the bushing caps. After a thorough cleaning, DurAlloy was applied to completely seal the failed joints. The engineers were so pleased with the results, the repair using DurAlloy and ENECON Field Support has become a standard procedure for the utility’s maintenance program.

Preparation: The first step was to strip away the old solder and any paint from the insulator bushing caps. This step is critical to ensure proper adhesion of the repair material and to eliminate any contaminants that might interfere with the repair.

Thorough Cleaning: Once the old solder and paint were removed, a thorough cleaning process was performed. This step ensures that the repair surface is free from dirt, grease, or any residue that could compromise the repair’s effectiveness.

DurAlloy Application: DurAlloy, a specialized repair material, was applied to completely seal the failed joints. DurAlloy is known for its durability, corrosion resistance, and ability to bond securely to various surfaces, making it an ideal choice for repairing complex and critical components like the insulator bushing caps.